September 8, 1892

HOISTING MACHINERY AND SAFETY CLUTCHES;

OTIS ELEVATING CABLE RAILWAY. (With inset.)

In our issue of Aug.

18 we gave a general description of the construction and equipment

of the Otis Elevating Cable Railway, up the eastern slope of the Catskill

Mountains, and called attention to some of the peculiarities of its

design. We show in the accompanying cuts and on our inset sheet this

week some general photographic views of the incline and complete details

of the hoisting machinery and safety devices,

In our issue of Aug.

18 we gave a general description of the construction and equipment

of the Otis Elevating Cable Railway, up the eastern slope of the Catskill

Mountains, and called attention to some of the peculiarities of its

design. We show in the accompanying cuts and on our inset sheet this

week some general photographic views of the incline and complete details

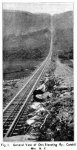

of the hoisting machinery and safety devices, which are used in its operation. It will be remembered that the incline

is 7,000 ft. long along the grade and has a rise of 1,630 ft., with

a maximum grade of 34%. Fig. 1

gives a general view of the line from a point near its bottom and shows

very clearly the construction of that portion of the track laid with

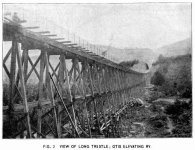

ballast in the ordinary manner. In Fig. 2

is shown a portion of the long trestle, detail drawings of which were

given in the previous article.

which are used in its operation. It will be remembered that the incline

is 7,000 ft. long along the grade and has a rise of 1,630 ft., with

a maximum grade of 34%. Fig. 1

gives a general view of the line from a point near its bottom and shows

very clearly the construction of that portion of the track laid with

ballast in the ordinary manner. In Fig. 2

is shown a portion of the long trestle, detail drawings of which were

given in the previous article.

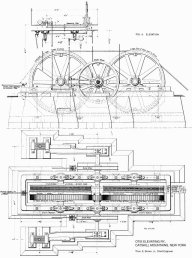

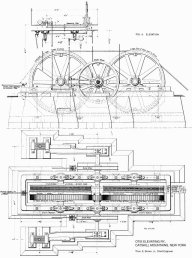

With regard to the hoisting machinery there is little

to be said in addition to the description given in the first article

which is not plainly shown by the  drawings.

In general it does not vary materially from that in use on other cable

inclines except, perhaps, in its magnitude and the unusual precautions

taken to insure safety in operating the road. It is located at the top

of the incline and consists in brief of two Hamilton-Corliss, reversing

engines, with 12 x 30 in. cylinders, driving a single shaft which is

geared to two spur wheels operating the drum shaft and winding drums.

The foundation is of brick and stone masonry on solid rock. The winding

drums are 12 ft. in diameter and are provided with six grooves for the

cables and also with seats for friction brakes, which are to be connected

with a suitable mechanism for throwing them into operation should the

car overrun its proper position at the station. In addition to the brakes

on the drums there are also friction brakes on the engine shaft which

an operated by one of the levers in the operating tower. drawings.

In general it does not vary materially from that in use on other cable

inclines except, perhaps, in its magnitude and the unusual precautions

taken to insure safety in operating the road. It is located at the top

of the incline and consists in brief of two Hamilton-Corliss, reversing

engines, with 12 x 30 in. cylinders, driving a single shaft which is

geared to two spur wheels operating the drum shaft and winding drums.

The foundation is of brick and stone masonry on solid rock. The winding

drums are 12 ft. in diameter and are provided with six grooves for the

cables and also with seats for friction brakes, which are to be connected

with a suitable mechanism for throwing them into operation should the

car overrun its proper position at the station. In addition to the brakes

on the drums there are also friction brakes on the engine shaft which

an operated by one of the levers in the operating tower.

As noted in the previous article, the machinery is

operated from a tower directly above and from which a clear view of

the whole line is had. This is accomplished by three systems of levers

operating the steam and reversing valves and the friction brakes on

the engine shaft.

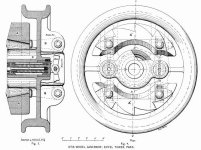

It will be seen that with the exception of the automatic

stop the operating of the safety devices connected with the hoisting

machinery is in the hands of the operator. To provide against accident,

should the operator become careless, or incapacitated for any cause,

or should the hauling cables break or stretch, safety clutches are attached

to each passenger car. These clutches are designed to work either when

one cable breaks or stretches unduly or when the car exceeds a certain

fixed rate of speed. Details of the clutches are shown in Figs.

7 & 11,  on

the inset sheet. They were designed by Mr. Thos. E. Brown, Jr., M. Am.

Soc. C. E. (to whom we are indebted for the blue prints, from which

our drawings are made), and are used for the first time on this line.

The operation of the clutches is as follows: Each set of two cables

after passing through guides is fastened by open sockets to the drawbars

which bear against the levers B, B, shown in Figs.

7 and 10. These levers swing upon the shaft E and bear

in turn against the frame D, which is keyed to the shaft E, and also

against the double pivoted plate or disk A. Should one of the cables

break or stretch sufficiently to about double the strain on the other,

the disk A revolves around one of the pivots through an angle limited

by the curved slots C, C, and the lever B, or B, attached to the unbroken

cable, swings forward moving the frame D, and causing the shaft E to

make a partial revolution. This causes the lever arm F, which is keyed

to the shaft and abuts against the spring G, to swing forward, thus

compressing the spring G, and causing a pull on the rod H, which is

connected with the long arm of the bell crank I. The bell crank I is

connected by the rod J to a second bell crank K (Fig.

9), which presses against the jaw L of the clutch, bringing it into

contact with the wooden guard rail. The movement of the jaw L, by means

of a system of levers, brings the other jaw of the clutch into contact

with the rail and the friction causes the clutch to swing back toward

the frame T, bringing the teeth into such a position that any forward

motion of the car increases the grip of the clutch. on

the inset sheet. They were designed by Mr. Thos. E. Brown, Jr., M. Am.

Soc. C. E. (to whom we are indebted for the blue prints, from which

our drawings are made), and are used for the first time on this line.

The operation of the clutches is as follows: Each set of two cables

after passing through guides is fastened by open sockets to the drawbars

which bear against the levers B, B, shown in Figs.

7 and 10. These levers swing upon the shaft E and bear

in turn against the frame D, which is keyed to the shaft E, and also

against the double pivoted plate or disk A. Should one of the cables

break or stretch sufficiently to about double the strain on the other,

the disk A revolves around one of the pivots through an angle limited

by the curved slots C, C, and the lever B, or B, attached to the unbroken

cable, swings forward moving the frame D, and causing the shaft E to

make a partial revolution. This causes the lever arm F, which is keyed

to the shaft and abuts against the spring G, to swing forward, thus

compressing the spring G, and causing a pull on the rod H, which is

connected with the long arm of the bell crank I. The bell crank I is

connected by the rod J to a second bell crank K (Fig.

9), which presses against the jaw L of the clutch, bringing it into

contact with the wooden guard rail. The movement of the jaw L, by means

of a system of levers, brings the other jaw of the clutch into contact

with the rail and the friction causes the clutch to swing back toward

the frame T, bringing the teeth into such a position that any forward

motion of the car increases the grip of the clutch.

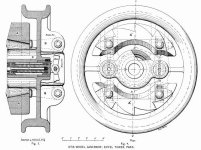

When the fixed rate of speed exceeds a certain limit,

12 miles per hour, the jaws of the clutch are thrown into action by

an entirely different mechanism, which is actuated by an Otis wheel

governor, shown in elevation at M. No details of this governor are given,

but its construction is exactly the same as the governor used with the Otis elevators in the Eiffel Tower, an elevation and section

of which are shown in Figs. 3 and 4.

It consists of two toothed weights shown in section at A, A, and in

elevation at A', A', (N, N, on inset Fig. 7). Each of these weights

is fastened to arms of two bell crank B, B, the other arms of Which

are pivoted to the sliding rods C, surrounded by spiral springs D. When

the revolutions of the wheels exceed a certain number per minute, the

weights tend to fly apart under the influence of centrifugal

force, this motion being allowed by the bell cranks and springs as plainly

shown in the figures.

used with the Otis elevators in the Eiffel Tower, an elevation and section

of which are shown in Figs. 3 and 4.

It consists of two toothed weights shown in section at A, A, and in

elevation at A', A', (N, N, on inset Fig. 7). Each of these weights

is fastened to arms of two bell crank B, B, the other arms of Which

are pivoted to the sliding rods C, surrounded by spiral springs D. When

the revolutions of the wheels exceed a certain number per minute, the

weights tend to fly apart under the influence of centrifugal

force, this motion being allowed by the bell cranks and springs as plainly

shown in the figures.

Turning now to the operation of the clutch, Figs.

7 and 8, it will be seen that as the weights N, N, fly

apart their teeth come in contact with the trigger O, fastened to one

end of a rocking shaft to the other end of which is attached a short

arm P, which locks with the nut Q on the rod R, and holds in compression

the spring S. When the teeth of the weights strike the trigger the rocking

shaft makes a partial revolution, lifting the arm P, and releasing the

spring S. This expands and presses the rod R against the long arm of

the bell crank I. This pressure is transmitted to the mechanism of the

clutch, causing it to operate in the manner already described. The whole

mechanism is very ingenious and all tests, both in the shops and on

the cars, have shown its operation to be effective. It would seem, however,

as if the construction lay open to the charge of unnecessary complexity.

The fewer parts such a mechanism has and the simpler these parts are

put together the better, generally speaking.

The contractors for the construction and equipment

of the road proper were given in our issue of Aug. 18. The contractors

for the engines and hoisting machinery were the Walker Mfg. Co., of

Cleveland, O., to whom we are indebted for the drawings of that machinery

shown on the inset. The safety clutches were manufactured by Otis Bros.

& Co., of New York City.

|

drawings

drawings